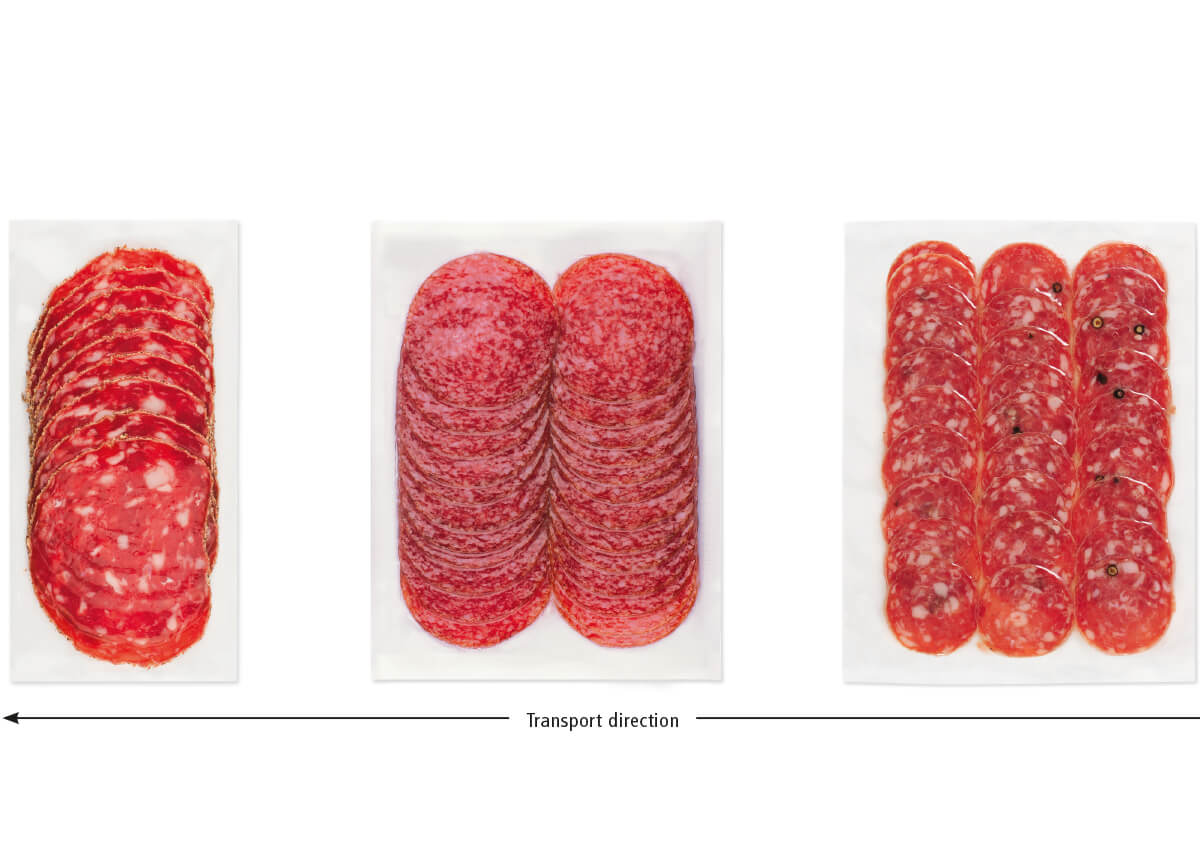

Vacuum packing machine for sliced products

Fully automatic vacuum packing machine for sliced or whole cuts with a height of up to 15 mm and from a minimum weight of 80 g on (depending on

the product and on the film). This in-line fully automatic packaging machine eliminates the costly labour of manually loading products into a bag. Another

advantage is that during the whole process the product is not being touched by hand and therefore it is extremely hygienically packed. The sliced product

from a fully automatic slicer is introduced via an in-feed conveyor to the vacuum packing machine. With photocells it measures the length of the product

in order to produce a bag with the exact length of the product. Once in the chamber the product is vacuum packed and as an option gas flushed (MAP)

and transported automatically on to an exit conveyor – the cycle is complete. The final step of this process could include an automatic or manual usage.

FastVac

Standard equipment

- Compressed air pressure sealing

- User-friendly SPS sensor control

- Vacuum pump: 60 cbm/h

- Gas flushing (MAP)

Options

- Vacuum pump: 106 or 151 cbm/h

- Extended infeed and exit conveyor with or without a stop switch

FastVac used in a production line

Products of different manufacturers, combined in one production line, may cause problems. The FASTVAC made by KOMET is best suitable to be integrated in complete production lines. In this way, e.g. slicers, vacuum packing machines, optionally a metal detector or an X-ray as well as a scale and a labeller can be combined in a production line. Thus, cutting, packaging, inspecting, weighing and labelling in one production line is easy.

The KOMET quality promise

KOMET grants a guarantee of 24 months on all machines – also, in the commercial sector. The guarantee includes the whole functioning of the machines. This ensures the customers that their newly purchased Komet products will also possess the promised properties and functions.