Thermoforming machine

The Sprinter is a unique solution in many ways. It is shorter and is more compact than other thermoforming machines without losing important features. With a shortness of only 2.7 m it can be used in very small rooms. In spite of its shortness, the Sprinter has three complete pack lengths open for loading the products, because of its extremely long loading station. This allows to work utmost rationally – even with more than one employee. The Sprinter guarantees up to 5 times the efficiency and speed of a normal chamber machine. The new lifting unit is reducing the air pressure consumption to a minimum. Therefore, the SPRINTER is not only unbeatable in its purchase costs but also in its operation costs.

Technical data:

- Top film (mm): 315 und 415

- Bottom film (mm): 322 und 422

Important: Compressed air connection as well as water inlet / outlet at the installation site are necessary!

Packing dimensions:

Standard machine shortness (Index 200 – 240 mm): 2.690 mm

- with conveyor belt (mm): 2.825

- Machine width 322 mm und 422 mm

Standard machine shortness (Index 260 – 300 mm): 3.110 mm

- with conveyor belt (mm): 3.245

- Machine width 322 mm und 422 mm

Vario tool

Standard equipment

- High performance vacuum pump 40 cbm/h

- Thermoforming from 5 mm to 100 mm adjustable in 5 mm steps

- Thermoforming tools are cooled with water

- Frame sealing

- Longitudinal cutting with rotating round knife

- Cross cutting with knife, hydraulic movement

- Discharge slide

- Vacuum controlled by sensor

- Programmable SPS control system

- 7“ touch panel with 256 colours, IP 65, user-friendly, multilingual

- 98 user programs adjustable

- Password protection

- Bottom film holder above forming station

- Outlet conveyor belt

- Certified and approved machine according to CE safety standards that are in line with the CE and European Hygiene and safety guidelines

- Pilz security technology

- Stainless steel switch cabinet IP 65, built according to the lastest guidelines and technology standards

- 2 separated heating systems for thermoforming and sealing, that can be individually set and programmed with the SPS control system

- Service opening for easy servicing of the vacuum pump

- Service-friendly chain tension system

- Easiest lubrication of the chain movement bearings

- Solid transport chain with a reinforced 5/8“configuration

- 10 different steps of transport speed

- Acceleration and slowing down of chain movement adjustable (important for liquid products)

- Energy savings through a vacuum pump with stand-by function

- Parts from worldwide known manufacturers

- Height adjustable stainless steel feet

- Easy and safe machine cleaning through a cleaning program

- Trim removal system with roll

Options

- Film width 322 mm or 422 mm

- Index length from 200 mm to 300 mm available in steps of 20 mm

- Water recirculation cooling system, reduces the water consumption and protects against subsequent costs due to calcifying.

- Payback period, depending on the useful life, after about 1.5 years

- Size about 72 x 80 x 50 cm

- Power connection via the machine

- Gas flushing system for MAP packaging incl. special pressure control system for faster and uniform gas injection

- Built-in or external high-performance vacuum pump 40, 60, 106 or 151 cbm/h

- Photo cell for printed top film with print marks incl. film brake

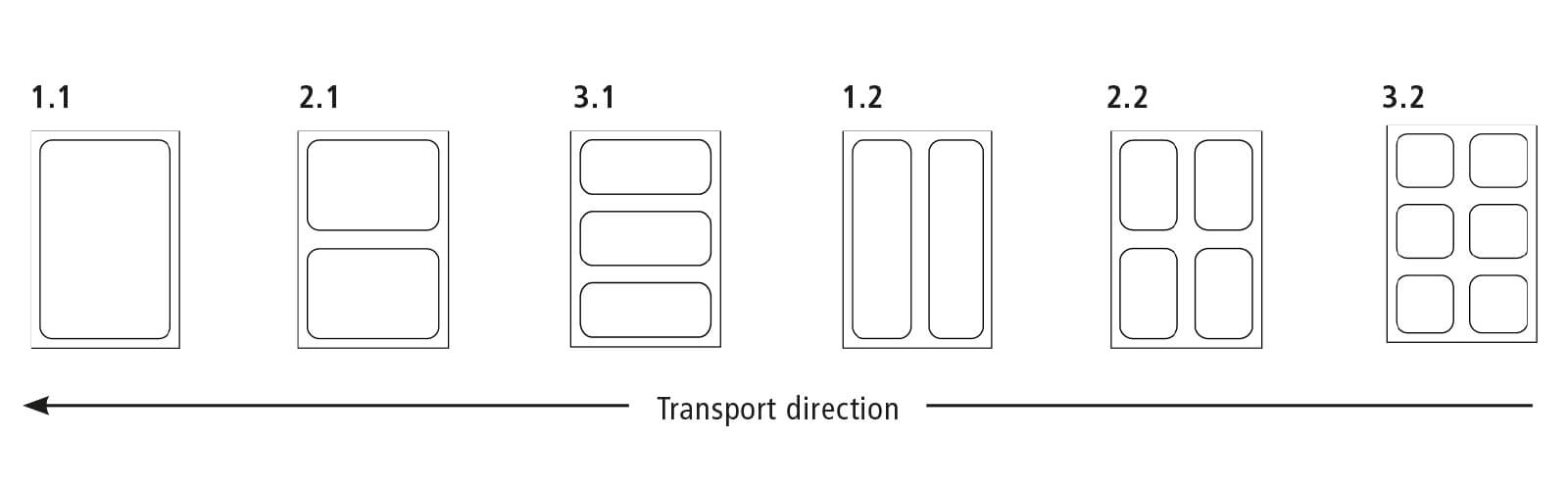

- Vario inserts (see on page 27)

- Additional stop bottom for the film movement on the forming station

- For flat products it would be possible to limit the movement of the tools from 100 mm to 50 mm

–> to get a higher cycle speed - Extension of the loading section

- Pressure control of gas, air and water supply

- Covers for the sealing edges in the loading area

- Flexi sealing plate suitable for all formats

The KOMET quality promise

KOMET grants a guarantee of 24 months on all machines – also, in the commercial sector. The guarantee includes the whole functioning of the machines. This ensures the customers that their newly purchased Komet products will also possess the promised properties and functions.